Thursday, November 21, 2024

Free Pallet Shed Plans: Create a Functional Shed for Your Backyard

Free Pallet Shed Plans: Create a Functional Shed for Your Backyard

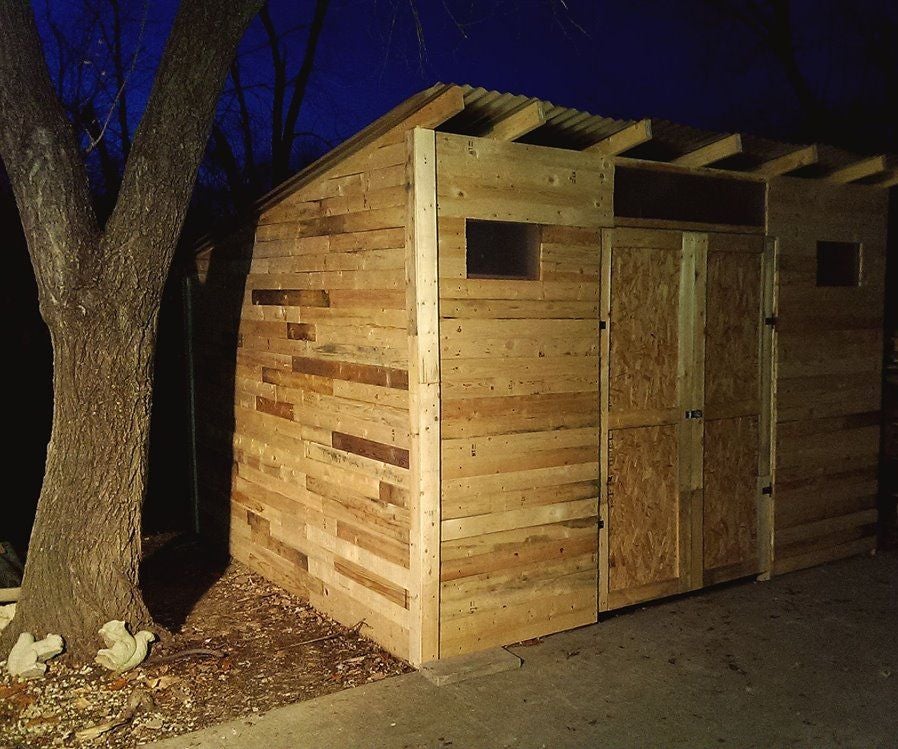

Tired of clutter piling up in your garage or overflowing from your garden shed? Yearning for a stylish and practical storage solution that won't break the bank? Look no further! This guide provides you with free pallet shed plans, empowering you to build a functional and attractive backyard shed using reclaimed pallets. We'll walk you through the entire process, from sourcing materials to the final touches, transforming those discarded pallets into a valuable asset.

Gathering Your Materials: The Foundation of Your Pallet Shed

Before you even think about hammering a nail, you need to gather your materials. This project thrives on recycling, so the star of the show is, of course, reclaimed wooden pallets. Inspect them carefully; choose sturdy pallets free of rot, significant damage, or embedded nails that could pose safety hazards. You'll need a sufficient number to construct the walls and roof. Beyond the pallets, gather essential supplies like:

- Screws and Nails: Opt for exterior-grade screws and galvanized nails to ensure longevity.

- Wood Primer and Paint/Stain: Protect your pallet shed from the elements and personalize its appearance with a durable coat of paint or stain.

- Plywood or OSB: This is crucial for creating a strong and weather-resistant roof and potentially for sheathing the walls for a more finished look.

- Roofing Material: Consider asphalt shingles, corrugated metal, or even recycled plastic roofing sheets for a durable and watertight roof.

- Tools: You'll need basic carpentry tools including a hammer, screwdriver (or drill), saw, measuring tape, level, and safety glasses.

Construction: Building Your Pallet Shed Step-by-Step

Creating the Foundation

Start by preparing a level base for your shed. This can be a simple concrete slab, a compacted gravel base, or even a level area of packed earth. The stability of your foundation directly impacts the longevity and structural integrity of your shed. Ensure the base is large enough to accommodate the dimensions of your planned shed. A slight overhang will provide protection to the walls from rain splash-back.

Assembling the Walls

Carefully dismantle any unusable parts of the pallets. Clean the remaining wood and assess its structural integrity. Begin constructing your walls by securely fastening pallets together vertically or horizontally, depending on your chosen design. Use screws for a stronger and more durable bond than nails. Remember to check the level and squareness of your walls frequently throughout the construction process to ensure a stable structure.

Constructing the Roof

Once the walls are erected, build the roof frame using additional wooden beams or repurposed pallet sections. You'll need to create a sturdy frame capable of supporting your chosen roofing material. Ensure the roof has a sufficient slope to allow rainwater to run off effectively. Finally, attach the chosen roofing material securely, creating a waterproof and weatherproof seal.

Adding Finishing Touches

Once the main structure is complete, add the finishing touches. This could include adding a simple door, windows for ventilation and natural light (using reclaimed materials where possible), and even shelving inside. A final coat of paint or stain will not only protect the wood but also enhance the aesthetic appeal of your pallet shed, transforming it from a simple storage space into a charming addition to your backyard. Consider adding a weatherproof sealant for ultimate protection.

Safety First: Essential Precautions

Safety should always be your top priority. Wear safety glasses and work gloves throughout the entire construction process. Handle pallets carefully as nails and splinters can cause injuries. If you’re unsure about any aspect of the construction, consult with a qualified professional before proceeding.

Building a pallet shed is a rewarding project that blends sustainability with practicality. By following these free pallet shed plans, you can create a functional and attractive storage solution without emptying your wallet. Enjoy the process and the satisfaction of transforming discarded materials into a valuable asset for your backyard!

How to Build a Rustic 10x12 Pallet Shed with Repurposed Materials

Building Your Dream Rustic 10x12 Pallet Shed: A Repurposed Paradise

Hey there, fellow DIY enthusiasts! So, you're dreaming of a rustic shed, a charming little sanctuary in your backyard, and you want to build it yourself using reclaimed materials? Fantastic! Building a 10x12 pallet shed is a totally doable project, even for someone with moderate DIY skills. It's a great way to save money, be environmentally conscious, and end up with a truly unique structure. Let's dive in and explore how to bring your vision to life!

Planning Your Pallet Paradise: The Foundation

Before you start hammering away, a little planning goes a long way. This isn't rocket science, but some forethought will save you headaches down the line. First, you've got to decide on the location. Consider sunlight, drainage, proximity to your house, and any local building regulations. You'll also want to check with your homeowner's association if applicable.

Choosing Your Palettes

Now for the fun part â€" sourcing your palettes! The quality of your pallets is crucial. Look for sturdy pallets made of heat-treated lumber (look for the HT stamp). Avoid pallets that show signs of significant rot, insect damage, or chemical treatments you're not comfortable with. Check with local businesses â€" construction sites, grocery stores, and even breweries are often happy to give away their used pallets. Just make sure to get permission first!

Gathering Your Tools and Materials

Beyond the pallets themselves, you'll need a few essential tools and materials. Don't worry, you probably have some of these already! Here's a basic list:

- Measuring tape

- Level

- Hammer

- Saw (circular saw or hand saw)

- Screws (exterior-grade, galvanized are best)

- Drill with drill bits

- Safety glasses

- Work gloves

- Post hole digger (if you're building on posts)

- Concrete mix (if you're using a concrete foundation)

- Optional: Nail gun (speeds things up considerably)

- Optional: Reclaimed wood for trim and accents

Remember, this is a rustic shed. Perfection isn't the goal. Embrace the imperfections of the reclaimed wood â€" they add to the charm!

Building the Foundation: Setting the Stage

Your foundation is the backbone of your shed. You have a couple of options:

Option 1: Concrete Slab

This is the most durable option, but it's also the most labor-intensive. You'll need to dig out the area, level the ground, create a formwork, and pour the concrete. Let it cure completely before moving on. This is probably best for heavier items stored in the shed.

Option 2: Pressure-Treated Wood Posts

A more affordable and quicker option. Dig holes for your posts, set them in concrete, and level them carefully. Make sure they’re deeply enough set into the ground to provide adequate support for the weight of the shed.

Framing Your Pallet Masterpiece

Once your foundation is solid, it's time to start building the frame of your shed. This involves using the pallets to create the walls. This will require some creativity, as pallets aren't standardized and will need adjusting.

Wall Construction

Carefully assess your pallets. Some might be damaged and unusable for load bearing. You'll likely need to disassemble some pallets to get the wood you need and get the framing right. Start by creating a frame for each wall using the sturdiest pallet planks. You can then attach the rest of the pallets to this frame to create the walls. Make sure to reinforce any weak points with additional bracing.

Roof Construction

For the roof, you can get creative. You could use more pallets, but that can add significant weight and might require more structural support. A more straightforward approach might be using plywood or even tarps for the roof structure if you want to keep things simpler and lighter.

Adding the Finishing Touches: Rustic Charm

With the basic structure complete, it's time to add those rustic finishing touches. This is where your creativity really shines! Consider adding reclaimed wood trim around the windows and doors, perhaps even a decorative gable. A coat of weather-resistant sealant will help protect your shed from the elements and enhance its rustic appeal. Don't forget a sturdy door â€" you could even repurpose an old door from a salvage yard!

Personalizing Your Shed

This is your chance to make this shed uniquely yours. Add some shelves inside, perhaps create a small workbench, or even paint it a fun color that complements your yard. You can add some vintage signs or other rustic décor to personalize the space.

Commonly Asked Questions

Q: How long will this project take?

A: This really depends on your experience and how much time you can dedicate to it. Expect to spend several weekends, maybe even a couple of weeks, if you're doing it yourself.

Q: How much will this cost?

A: The beauty of this project is that it can be very affordable. The biggest expense will likely be the screws, sealant, and any additional materials you need beyond the pallets themselves. Your costs will vary greatly depending on your location and materials used.

Q: Do I need any special permits?

A: Check with your local authorities. Depending on your location and the size of your shed, you may need a permit. It’s better to be safe than sorry and check beforehand!

Q: What if I'm not very handy?

A: Don't worry! This project is designed to be approachable for DIYers of all skill levels. There are tons of online resources and videos to guide you through each step. Don't be afraid to ask for help from friends or family if you get stuck!

There you have it! Building a rustic pallet shed is a rewarding project that combines creativity, resourcefulness, and a whole lot of fun. Get started on your dream shed today!

Wednesday, November 20, 2024

Transform an Empty Corner Into a Lean-To Shed with These Simple Plans

Transform an Empty Corner Into a Lean-To Shed with These Simple Plans

Tired of clutter piling up? Wish you had a little extra storage space, but lack the budget or expertise for a full-blown shed construction? Then consider transforming that neglected corner of your yard into a practical and attractive lean-to shed! This project, achievable even for novice DIYers, offers a surprisingly spacious storage solution with minimal materials and effort. Follow these simple plans and watch your empty corner blossom into a functional addition to your property.

Planning Your Lean-To Shed

Before you grab your tools, careful planning ensures a successful project. First, choose your location wisely. Consider proximity to your house for easy access, existing structures that can serve as support, and adequate sunlight for drying materials if necessary. Next, determine the dimensions. A lean-to's size depends on your storage needs and available space. Sketch a simple plan, noting the desired length and width, along with the height at the peak of the roof. Finally, acquire necessary permits. Local building codes vary; check with your municipality to confirm if permits are required for your lean-to shed project and acquire them before commencing construction.

Gathering Your Materials

This project emphasizes simplicity and affordability. Your material list will include pressure-treated lumber for durability, roofing materials (consider asphalt shingles for ease of installation), screws or nails, concrete blocks (or alternative anchoring system) for the base, and a level to ensure a stable structure. Don't forget essential safety gear like safety glasses and work gloves! A detailed list, based on your shed's dimensions, should be compiled before heading to your local hardware store. Remember to consider the weight your lean-to will bear â€" selecting robust materials is crucial for longevity.

Detailed Materials List (Example for a 6ft x 4ft Shed):

- Four 6ft pressure-treated 4x4 posts for the base.

- Six 6ft pressure-treated 2x4s for the frame.

- Several 6ft pressure-treated 2x4s for roofing support rafters.

- Plywood or OSB sheeting for walls (optional).

- Asphalt shingles or other roofing material.

- Concrete blocks or other anchoring system.

- Screws or nails, appropriate for the wood type.

- Level, measuring tape, saw.

Step-by-Step Construction

Begin by preparing the base. Level the ground where your shed will be placed and set your concrete blocks or other anchoring system for the base. These will firmly anchor your 4x4 posts, which will form the foundation of your lean-to. Next, construct the frame. Attach the 2x4s to the posts, ensuring squareness and stability. This creates the skeleton of your lean-to. Now, add the roofing supports â€" these rafters should be properly spaced and securely attached to the frame to support the weight of the roofing material. Finally, install the roofing, carefully overlapping the shingles to ensure a weathertight seal. You can add optional walls using plywood or OSB for extra privacy and storage.

Finishing Touches and Considerations

Once the construction is complete, consider adding a simple door for easy access. This can be as simple as a framed opening covered with plywood and hinges. Think about adding weather stripping around the door and along the base to prevent drafts and moisture. Painting the shed adds both aesthetic appeal and protection from the elements. A coat of exterior-grade paint or stain will significantly extend the life of your lean-to. Remember to regularly inspect your shed for any signs of wear and tear and address them promptly to maintain its structural integrity. With a little care and maintenance, your DIY lean-to shed will provide years of reliable storage.

Saturday, November 16, 2024

Designing a Lofted Shed with 12x20 Plans for Storage and Function

Building Your Dream 12x20 Lofted Shed: Storage, Space, and So Much More!

So, you're thinking about building a shed? Fantastic! But not just *any* shed â€" you want a 12x20 lofted shed, maximizing space and functionality. That’s awesome! This is a project that can really transform your property, adding valuable storage and maybe even a fun little workshop space. Let's dive into the exciting world of lofted shed design and construction.

Planning Your 12x20 Lofted Shed Masterpiece

Before you even think about grabbing a hammer, careful planning is key. This isn't about slapping together some boards; we're talking about building something sturdy and useful that will last for years. Think of it as a mini-construction project!

Choosing the Right Location

Where will your magnificent shed reside? Consider these factors:

- Accessibility: Will you need a vehicle to access it? Make sure there's enough space for maneuvering.

- Sunlight: Do you need natural light for a workshop? Consider sun exposure when choosing your spot.

- Drainage: Avoid low-lying areas prone to flooding. You’ll want a dry foundation.

- Utilities: If you're planning on electricity or running water, consider proximity to existing lines. This might affect your final location choice.

- Local Regulations: Check with your local council or homeowner's association about building permits, setbacks, and any restrictions on shed size or design.

Designing for Function

Think about how you plan to use your shed. This will drastically influence the design. Will it be primarily for storage, or will you have a workshop area? Maybe even a small potting shed? Knowing this will help you decide on things like:

- Loft Access: Will you need a fixed staircase, a pull-down ladder, or something else entirely?

- Window placement: More windows mean more light, but also less wall space for shelving.

- Door placement and size: Consider the size of items you'll be storing or moving in and out of the shed.

- Workbenches and shelving: Plan the layout carefully, thinking about workflow and accessibility.

Materials: Building the Foundation

Choosing the right materials is crucial for longevity and durability. Let's talk about the main players:

- Foundation: A concrete slab provides a solid, level base. Gravel foundations are also a viable, albeit less expensive option. But remember that a poor foundation can lead to issues down the line.

- Framing: Pressure-treated lumber is your friend. It's resistant to rot and insects, essential for a long-lasting shed.

- Siding: Vinyl, metal, or wood â€" the choice is yours. Each material has its pros and cons regarding cost, maintenance, and aesthetics. Metal is highly durable and low maintenance, while wood offers a more rustic look.

- Roofing: Asphalt shingles are a popular and relatively inexpensive choice. Metal roofing is another durable option, offering superior protection from the elements.

Construction: Building Your 12x20 Shed

This part's exciting, but remember safety first! If you're not confident in your DIY skills, consider hiring a professional. Otherwise, let's get building!

Step-by-Step Guide (Simplified!):

This is a high-level overview â€" each step involves numerous sub-steps. Always refer to detailed plans and tutorials.

- Foundation: Prepare your chosen foundation, ensuring it's level and solid.

- Framing: Construct the walls and roof frame, ensuring squareness and proper bracing.

- Sheathing: Install sheathing (plywood or OSB) over the framing for added strength and a surface to attach siding to.

- Siding and Roofing: Install your chosen siding and roofing materials, following manufacturer instructions carefully.

- Loft Construction: Build the loft floor joists and decking, ensuring proper support and access.

- Finishing Touches: Install doors, windows, trim, and any interior features.

Important Considerations During Construction:

- Building Codes: Adhere to all local building codes and regulations.

- Safety First: Wear appropriate safety gear, including safety glasses, gloves, and hearing protection.

- Weather Conditions: Work on dry days when possible. Rain can significantly delay the project and damage materials.

- Take Breaks!: Building a shed is hard work. Take regular breaks to avoid fatigue and injury.

Adding the Finishing Touches to Your Shed

Once the structure is up, the fun part begins! Personalizing your shed makes it truly yours.

Interior Design and Organization

Think about your storage needs and how to maximize the space. Shelving, pegboards, and cabinets can help keep things organized and easily accessible. If you're using the space as a workshop, consider dedicated areas for tools and projects. Proper lighting is also essential, no matter the use.

Exterior Aesthetics

Consider adding some landscaping around your shed to make it blend seamlessly with your property. A simple paint job can transform the look and feel, and adding decorative elements such as shutters or a weather vane can add personality.

Commonly Asked Questions

Let's tackle some frequently asked questions about 12x20 lofted sheds.

Q: How much does it cost to build a 12x20 lofted shed?

A: Costs vary widely depending on materials, location, and labor. Expect to spend anywhere from $3,000 to $10,000 or more. Using more affordable materials and doing the work yourself will significantly lower costs.

Q: Do I need a building permit?

A: This depends entirely on your local regulations. Check with your local council or homeowner's association before you start building.

Q: How long does it take to build a 12x20 lofted shed?

A: This varies greatly depending on experience, the complexity of the design, and weather conditions. Expect it to take anywhere from a few weekends to several weeks, even months for those new to construction.

Q: What are the best materials for a lofted shed?

A: Pressure-treated lumber for framing, metal or vinyl siding for durability, and asphalt or metal roofing are all popular choices. The best choice depends on your budget, aesthetic preferences, and climate.

Q: Can I add electricity to my shed?

A: Yes, but this requires an electrician to ensure it's done safely and to code. You'll likely need to obtain additional permits.

Building a 12x20 lofted shed is a rewarding project. With careful planning, attention to detail, and a bit of elbow grease, you'll create a valuable addition to your property that you’ll enjoy for years to come!

Monday, November 11, 2024

How to Build a Pole Barn with a Pre-Cut Kit for Quick Assembly

Alright, so you've decided to go for it - you're building a pole barn! That's awesome. You're joining the ranks of DIYers who love the freedom and satisfaction that comes with building something yourself.

And you've chosen a pre-cut kit? Smart move! It takes a lot of the guesswork out of the project and speeds things up. But let's be real, "quick" and "weekend" are relative terms when it comes to building. But hey, with a little planning and a good crew (or a really dedicated friend), you can get a roof over your head (or your equipment) in a reasonable amount of time.

Here's a breakdown of what you need to know to build your pole barn:

1. The Basics - Planning and Preparation

First things first, you need to do your homework. This is where you lay out the foundation for your project, literally and figuratively.

Get the Right Permits: Before you even think about digging a hole, check with your local building department. They'll tell you what permits you need, any specific building codes you have to follow, and maybe even offer some helpful tips. It's better to be safe than sorry, right?

Choose Your Kit: There are tons of options when it comes to pre-cut pole barn kits. You can get kits for simple structures to kits that include everything you need for a full-fledged workshop or garage. Decide what size, features, and materials you need. This will help you narrow down your choices and find the right kit for your needs.

Site Prep: This is where the fun begins! You need to clear the area where your barn will be built. Remove trees, rocks, and anything else that might get in your way. You'll also need to level the ground and compact it for a solid foundation. If you're in a hilly area, you might need to do some grading.

Setting the Foundation: This is where you'll dig those holes! You'll need to create sturdy footings for your pole barn. The depth and size of the footings will depend on the size of the barn and local soil conditions. Concrete footings are the most common and durable option.

2. Assembling the Frame: The Skeleton of Your Barn

Now it's time to get those poles up!

Erect the Posts: This is where having a good crew comes in handy. You'll need to lift the pre-cut posts into the concrete footings and plumb them carefully. Make sure they're all level and straight! A good level is your best friend here.

Attaching the Beams: Once the posts are secure, you can start attaching the roof beams. This involves lifting the beams and securing them to the tops of the posts. You'll need to make sure the beams are level and properly aligned.

Adding the Braces: Braces provide stability and support to your barn's structure. You'll typically find a variety of bracing elements in your kit. Install them according to the manufacturer's instructions.

Installing the Wall Panels: Depending on the kit, you might have pre-made wall panels or individual pieces of wall siding. These will be attached to the posts, and often secured with a variety of fasteners.

3. Roofing and Finishing Touches:

Roofing: Once the frame is complete, it's time for the roof. Most kits come with pre-cut roof trusses and plywood sheathing. Install the trusses and sheathing, then you can move on to the roofing material. The type of roofing you choose will depend on your budget and the climate where you live.

Doors and Windows: Now you'll install doors and windows. This is a good time to check and double check that your openings are the correct size and that you have everything you need to get them installed.

Siding and Trim: The final step is adding the siding and trim. This is where you can personalize your pole barn and give it that final touch. Again, the kit you choose will often determine the types of siding and trim that are included.

4. Safety First and Always

Let's be real - working with wood, power tools, and a whole lot of weight can be dangerous if you're not careful.

Wear Proper Safety Gear: This includes safety glasses, hearing protection, work gloves, and steel-toe boots.

Use Tools Safely: Make sure you know how to use all of the tools you're working with, and follow the manufacturer's instructions.

Don't Take Shortcuts: This is not the time to be impatient. Take your time and do everything carefully. A little extra time spent getting things right can save you a lot of hassle in the long run.

5. Tips for Success

Read the Instructions: This might sound obvious, but it's important to carefully read the instructions that come with your kit. They'll provide step-by-step guidance and helpful tips.

Have the Right Tools: Make sure you have all the necessary tools before you start building. This might include a level, hammer, saw, drill, tape measure, and safety gear.

Plan Your Work: Before you start building, it's a good idea to sketch out a rough plan of how you'll assemble the barn. This will help you visualize the process and make sure you have everything you need.

Ask for Help: Don't be afraid to ask for help if you need it. There are plenty of resources available online and in your community.

Building a pole barn from a pre-cut kit is a great way to save time and money. It's also a fun and rewarding project that can help you improve your DIY skills.

So, go get that kit, gather your friends, and start building! Just remember to be safe, take your time, and enjoy the process.

How to Build a Pole Barn with a Large Overhang for Extra Protection

Pole barns, with their straightforward construction and adaptable design, are popular structures for a multitude of purposes, from workshops and garages to livestock shelters and storage facilities. A key element often overlooked in their design, however, is the potential for extended overhangs. A large overhang not only adds aesthetic appeal but also serves as a significant protective element for the structure and its contents. This article will delve into the intricacies of building a pole barn with an expansive overhang, offering comprehensive guidance on design, materials, and construction techniques.

Design Considerations:

1. Purpose and Usage: Before embarking on the project, it is crucial to define the intended use of the pole barn. This will inform critical aspects of the design, including the size, height, and overall configuration of the overhang. A workshop may require a larger overhang than a simple storage shed, and a livestock shelter may necessitate a more robust design.

2. Local Regulations and Building Codes: Each municipality has specific codes and regulations governing building structures. Research local building codes prior to design and construction to ensure compliance and avoid costly setbacks. This includes factors such as minimum distance from property lines, required foundation types, and permitted roofing materials.

3. Site Conditions: The site where the pole barn will be erected plays a critical role in the design. Factors such as soil type, terrain, and existing utilities must be considered. Additionally, the presence of trees, power lines, or other obstacles should be factored in to prevent interference with the structure.

4. Overhang Size and Shape: The size and shape of the overhang are crucial for its effectiveness. A wider overhang offers greater protection from rain, snow, and sun, while a deeper overhang provides more shelter for vehicles or equipment. Consider the intended use and the prevailing weather conditions when determining the desired size and shape. A common approach is to extend the roofline beyond the wall by 2-3 feet for basic protection, while larger overhangs may extend up to 5-6 feet.

5. Roofing Materials and Pitch: The roofing material selected for the overhang will greatly influence its durability, aesthetics, and cost. Consider factors such as weight, weather resistance, and maintenance requirements. The roof pitch also plays a crucial role in snow and rainwater drainage. A steeper pitch, typically 6:12 or greater, promotes efficient water runoff and prevents snow accumulation.

6. Foundation and Support Structure: The foundation must be designed to accommodate the added weight and load of the overhang. Concrete piers or footings are common foundation choices for pole barns. The support structure, typically consisting of beams and posts, must be robust enough to support the overhang's weight and withstand environmental forces. Additional support posts or beams may be required for larger overhangs.

Materials and Construction:

1. Posts: Pressure-treated lumber is the ideal material for the posts, as it resists rot and decay. The size and spacing of the posts will depend on the overall dimensions of the pole barn and the weight of the overhang. Consider using 6x6 or 8x8 posts for larger overhangs.

2. Beams and Trusses: Strong and durable beams are crucial for supporting the roof and overhang. Glulam beams, engineered lumber, or heavy-duty dimensional lumber can be used, depending on the size and load requirements. Consider using trusses instead of beams, particularly for wide overhangs, as they offer superior strength and stability.

3. Roofing System: The roofing system comprises the sheathing, underlayment, and roofing material. For a strong and durable roof, plywood or OSB sheathing is recommended. An underlayment, such as felt or synthetic felt, acts as a barrier against moisture penetration. The chosen roofing material, whether asphalt shingles, metal roofing, or another option, should be compatible with the local climate and building codes.

4. Framing and Siding: The framing for the overhang is typically constructed using dimensional lumber, creating a frame that supports the roof and siding. The siding can be a variety of materials, including wood, metal, or composite, depending on the desired aesthetic and budget.

5. Drainage and Gutters: Proper drainage is essential to prevent water buildup and potential damage to the structure. Install gutters along the edges of the overhang to collect and direct rainwater away from the building. Downspouts should be connected to gutters and extend to the ground to prevent water from pooling around the foundation.

Construction Steps:

1. Site Preparation: Clear the site of vegetation and debris, and level the ground for the foundation. Ensure proper drainage to prevent water from pooling near the structure.

2. Foundation Installation: Install the foundation according to the design specifications and local building codes. Concrete piers or footings are commonly used for pole barn foundations.

3. Post Erection: Install the posts at the designated locations, ensuring they are plumb and level. Secure the posts to the foundation using concrete or metal brackets.

4. Beam Installation: Place the beams on top of the posts and securely attach them using brackets or other appropriate methods. Ensure the beams are level and aligned.

5. Roof Construction: Construct the roof system, including sheathing, underlayment, and roofing material. For large overhangs, consider using trusses instead of beams for optimal support.

6. Framing and Siding: Frame the overhang using dimensional lumber, and attach the siding to the frame. Ensure proper ventilation is provided to prevent moisture buildup.

7. Drainage and Gutters: Install gutters and downspouts along the edges of the overhang to direct rainwater away from the building.

8. Finishing Touches: Add finishing touches, such as trim, soffits, and fascia, to enhance the appearance of the overhang.

Benefits of a Large Overhang:

1. Protection from the Elements: A generous overhang provides significant protection from rain, snow, and sun, keeping the structure and its contents dry and cool.

2. Extended Storage Space: The overhang creates additional covered space that can be used for storage, work areas, or recreational activities.

3. Enhanced Aesthetics: A well-designed overhang adds aesthetic appeal to the pole barn, enhancing its overall appearance.

4. Increased Durability: The overhang shields the walls and roof from direct exposure to the elements, extending their lifespan and reducing maintenance requirements.

5. Increased Energy Efficiency: The overhang can provide shade during the summer months, reducing heat gain and lowering cooling costs.

Conclusion:

Constructing a pole barn with a generous overhang requires careful planning, proper materials selection, and skilled craftsmanship. By following the guidelines outlined in this article, homeowners and builders can create a durable and attractive structure that provides enhanced protection and functionality. The benefits of a well-designed overhang extend beyond mere aesthetics, offering practical advantages for a multitude of applications. Investing in a large overhang is a wise decision for those seeking a sturdy, adaptable, and visually appealing pole barn structure.

How to Build a Pole Barn with Custom Wall Features

The classic pole barn design, with its simple construction and versatile application, remains a popular choice for a variety of purposes. However, many seek to elevate this traditional design by incorporating custom wall features, adding both aesthetic appeal and functional enhancements. This article provides a detailed guide to building a pole barn with personalized touches, covering essential steps from planning to execution.

1. Planning and Design:

A. Define the Purpose and Scope:

Functionality: Determine the primary use of the pole barn. Will it be a workshop, a garage, a storage facility, a barn for livestock, or a combination thereof?

Size and Layout: Carefully consider the required square footage and optimize the layout for efficient use of space.

Budget: Set a realistic budget and prioritize features that align with your needs and financial constraints.

B. Explore Custom Wall Features:

Windows and Doors: Consider the size, shape, and placement of windows and doors to maximize natural light, ventilation, and accessibility.

Walls: Explore different wall finishes such as siding, stone, or brick for aesthetic appeal and durability.

Interior Finishes: Plan for interior walls, ceilings, and flooring options that suit your desired ambiance and functionality.

Insulation and Climate Control: Evaluate your climate and consider the level of insulation required for comfort and energy efficiency.

C. Secure Necessary Permits:

Contact your local building department to obtain all required permits and ensure compliance with local codes.

Be prepared to provide detailed plans, specifications, and engineering calculations for review.

2. Site Preparation and Foundation:

A. Site Selection:

Choose a level site with adequate drainage to prevent water accumulation around the building.

Ensure access for construction vehicles and the delivery of materials.

B. Foundation Construction:

Concrete Piers: Concrete piers are the most common foundation type for pole barns. They are durable, economical, and require less excavation.

Precast Concrete Columns: Precast concrete columns offer a quicker construction process and can be tailored to specific design requirements.

Steel Posts: Steel posts provide strength and durability but require proper treatment for corrosion resistance.

3. Framing and Roof Construction:

A. Framing:

Posts: Use pressure-treated lumber or steel posts for the structural framework.

Beams: Securely attach beams to the posts to support the roof and walls.

Rafters: Construct the roof framing with rafters that span the beams and provide support for the roof sheathing.

B. Roof Construction:

Sheathing: Install roof sheathing over the rafters to provide a solid base for roofing materials.

Roofing: Choose a roofing material that suits your budget, aesthetic preference, and climate.

Ventilation: Ensure proper ventilation to prevent moisture buildup and maintain a comfortable interior temperature.

4. Custom Wall Construction:

A. Exterior Walls:

Framing: Build the wall framing using studs and bracing.

Insulation: Install insulation within the wall cavities to enhance energy efficiency and reduce noise.

Sheathing: Cover the framing with sheathing to provide a smooth surface for the exterior finish.

Exterior Finish: Choose a siding material that complements your design and offers desired durability.

B. Interior Walls:

Framing: Construct interior wall framing using studs and bracing.

Insulation: Install insulation within the wall cavities for thermal comfort and noise reduction.

Interior Finish: Apply desired interior finishes such as drywall, paneling, or other options that meet your design and functional needs.

5. Windows and Doors:

A. Window Installation:

Carefully measure and cut openings in the walls for windows.

Install windows using flashing and sealant to ensure proper water resistance.

Consider the type and size of windows based on desired light and ventilation.

B. Door Installation:

Prepare the door openings in the walls.

Install doors using hinges, latches, and weatherstripping for smooth operation and weatherproofing.

6. Finishing Touches:

A. Electrical and Plumbing:

Plan and install electrical wiring, plumbing, and other utilities according to local codes and safety regulations.

Consider the placement of electrical outlets, lighting fixtures, and other necessary features.

B. Flooring:

Install flooring that suits your desired aesthetic and functionality.

Options include concrete, wood, tile, epoxy coatings, and more.

C. Painting and Decorating:

Paint the interior and exterior walls to enhance the aesthetic appeal and provide a protective layer.

Consider adding decorative elements such as trim, moldings, and custom finishes.

7. Final Inspections and Completion:

Conduct thorough inspections of all construction elements to ensure compliance with codes and specifications.

Obtain necessary permits and approvals for occupancy.

Complete all landscaping, site cleanup, and final touches to create a finished and functional pole barn.

Customizing Your Pole Barn:

By incorporating custom wall features, you can create a pole barn that surpasses traditional designs. Here are some ideas:

Custom-designed Windows: Explore unique shapes, sizes, and placements to create a distinctive aesthetic and optimize natural light.

Stone or Brick Accents: Add a touch of elegance and durability with stone or brick veneers for select walls.

Custom-built Doors: Choose unique door styles and materials to create an impressive entrance.

Built-in Storage Solutions: Design custom cabinets, shelves, and storage systems to maximize space efficiency.

Interior Design Features: Incorporate wood paneling, vaulted ceilings, or other unique features to create a personalized ambiance.

Conclusion:

Building a pole barn with custom wall features requires careful planning, attention to detail, and skilled craftsmanship. By following the steps outlined above, you can create a versatile and personalized structure that meets your specific needs and aesthetic preferences. Remember to consult with professionals for design guidance, construction expertise, and code compliance. With careful planning and execution, you can build a pole barn that serves its purpose while standing as a testament to your individual style and vision.

The cheapest pole shed plans for diy construction

Alright, so you're thinking about building a pole barn, huh? Maybe you're tired of paying for storage, or maybe you need a workspace, or maybe you just have a vision of a sweet little she-shed in your backyard. Whatever the reason, you're in the right place. We're going to talk about how to get the cheapest pole barn plans possible, and I'm gonna talk to you like a friend, no fancy jargon or anything, just straight talk.

Why Pole Barns?

Okay, first things first, why are pole barns so popular? Well, they're basically the IKEA of buildings. They're super affordable, and you can DIY them, which saves a ton of money. You're essentially building a frame out of posts, and then covering that frame with walls and a roof. It's pretty simple, and that's part of the appeal. They're also really versatile. You can build them big or small, and you can customize them to fit your needs. You can even add windows and doors.

Cheapest Pole Barn Plans: Where to Start?

Now, let's get down to the nitty-gritty. You want the cheapest pole barn plans possible, right? Well, there are a few different ways to go about this.

1. The Free Route: You can try finding free pole barn plans online. There are websites like Pinterest, Google Images, and even some building supply websites that offer free plans. The problem? These plans might not be designed by professionals, and they could be lacking in some important details. You might end up with a shaky building if you're not careful.

2. The DIY Route: If you're handy, you can draft your own plans. There are plenty of resources available to help you with this, including online tutorials and books. This can be a fun way to get creative and personalize your building, but it takes some time and effort. And if you're not comfortable with drafting plans, this might not be the best option.

3. The Online Marketplace Route: You can find tons of pre-made plans online. Sites like Etsy and eBay have a lot of sellers who offer DIY plans, often for a very reasonable price. You'll want to be careful, though. Make sure to check the seller's reviews, and make sure that the plans are actually well-designed.

4. The Professional Route: If you want to be sure that your plans are top-notch, you can hire an architect or engineer to draw up your plans for you. This is obviously the most expensive option, but it's also the safest. A professional will ensure that your building is structurally sound and meets all the necessary building codes.

Important Tips for Finding Cheap Pole Barn Plans

Here are some extra tips for finding the cheapest pole barn plans:

Think About the Basics: First, figure out what size and shape you need. This will narrow your search. Do you need a shed for tools, or a large workshop, or something else entirely?

Get Creative: Explore different designs. Maybe you can use reclaimed materials or repurposed items for some of your building elements. This can save a lot of money!

Consider the Permits: Before you start building, check your local building codes. You might need to obtain permits, and there may be restrictions on the size and design of your pole barn. This might affect your plans, but it's important to stay on the right side of the law.

Think About the Future: Even though you want to save money now, consider how you might need to use your building in the future. If you might need to expand it later, you can design your plans with that in mind.

Take Your Time: Don't rush into buying the first plans you see. Do your research and compare prices before you make a decision.

Beyond the Plans: Saving Money on Your Pole Barn Build

Okay, you've got your plans sorted out, but that's just the tip of the iceberg. Here's how to keep costs down when building your pole barn:

Materials: Shop around for the best prices on materials. Check multiple suppliers, and consider using reclaimed or salvaged materials.

Labor: If you're handy, try to do as much of the work yourself as possible. This will save you a lot of money on labor costs.

Tools: You'll need some basic tools for building a pole barn, but you can often rent or borrow tools instead of buying them.

Time: Take your time. It's better to take a little longer and do the work right than to rush and make mistakes.

Safety: Safety first! Don't try to take shortcuts or skip safety precautions. A safe build is a successful build.

The Bottom Line: It's Possible!

Finding the cheapest pole barn plans is all about planning and getting creative. You can do it! Just remember to be patient, do your research, and most importantly, have fun with the process. Building your own pole barn is a great way to save money and build something you can be proud of. Good luck, you got this!

Sunday, November 10, 2024

Step-by-step guide for building a lean-to shed with ease

Hey there, DIY enthusiasts! Ever dream of having a little extra space in your backyard? A place to store tools, bikes, or maybe just a quiet spot to relax with a good book? Well, you're in luck because building a lean-to shed is easier than you think! It's a perfect project for beginners, and with my step-by-step guide, you'll have your own little backyard oasis in no time.

Let's Get Started:

1. Planning Your Paradise: Before you even think about grabbing a hammer, let's get organized. First, decide where you want your lean-to shed. Make sure it's a level spot, ideally against a sturdy wall like your house or a garage. Next, consider the size. How much stuff do you need to store? A basic 8x10 shed is a good starting point, but you can always adjust to your needs.

2. Gather Your Supplies: This is where your shopping list comes in handy. You'll need the basic building materials like lumber for the frame, plywood for the walls and roof, roofing shingles, and fasteners like screws and nails. For the foundation, you'll need concrete blocks or pressure-treated lumber. Remember, you can always swap out certain materials based on your budget and personal preferences.

3. Laying Down the Foundation: Alright, time to get our hands dirty! First, prepare the area by clearing away any debris and leveling the ground. For a simple foundation, you can use concrete blocks laid on a bed of gravel. Make sure they're level and secure. You can also build a raised foundation with pressure-treated lumber, which is a great choice if you're on uneven ground.

4. Framing Your Future: Now comes the fun part - building the frame! Start by cutting your lumber to size. Use the measurements you determined in the planning stage. For a simple lean-to, you'll need four vertical posts and a series of horizontal beams. Remember, the steeper the roof angle, the more sturdy it will be. Connect these pieces with screws or nails, ensuring everything is square and stable.

5. Adding the Roof: Here comes the roof! First, you'll need to install the roof rafters. These run from the top of the wall to the ridge of the roof. Space them evenly, typically 16 inches apart. Once you have your rafters in place, you can sheathe the roof with plywood. Now it's time for the finishing touch - shingles! Choose a style you like and follow the manufacturer's instructions for installation.

6. Building the Walls: With the frame and roof in place, it's time to add the walls. Cut your plywood sheets to size and attach them to the frame using screws or nails. Remember to leave an opening for your door. You can install a pre-made door or build your own with some simple framing techniques.

7. Finishing Touches: We're almost there! Time to add the finishing touches. First, you can install siding, paint, or even stain the wood to personalize your shed. Don't forget about the windows. Choose the size and style that fits your needs and install them carefully. Finally, add a floor to your shed. You can use plywood, concrete, or even composite decking for a more durable finish.

8. Finishing Touches: Almost there! Now's the time to add those personal touches that make your shed truly yours. Choose siding, paint, or stain to match your style. Don't forget about windows! Pick a size and style that fits your needs and install them carefully. Finally, add a floor to your shed. You can use plywood, concrete, or even composite decking for a durable finish.

Extra Tips for a Successful Build:

Double-check your measurements: Accuracy is key! Take your time and make sure everything is precisely measured before cutting any lumber. You can always measure twice and cut once.

Use proper safety gear: Always wear safety glasses, work gloves, and a dust mask when working with power tools and wood.

Take your time: Don't rush the process. Enjoy building your shed and take pride in your craftsmanship. Remember, you can always ask for help from a friend or family member if you need it.

Building a lean-to shed is a rewarding experience! You'll enjoy the satisfaction of creating something with your own two hands and having a fantastic new space in your backyard. With a little planning, effort, and this step-by-step guide, you'll be well on your way to building your own lean-to paradise!

Bonus Tip: Don't forget to personalize your shed with some fun decorations! Hang up some plants, add some storage shelves, or even install a small lighting fixture to create a cozy and inviting atmosphere. Let your creativity run wild! And remember, you can always update and improve your shed over time as your needs change. Building is a process, and there's no need to get everything perfect on the first try. Enjoy the journey!

Saturday, November 9, 2024

Diy 8x12 shed: design it, build it, save big

Alright, folks, let's talk sheds! You know that feeling, right? You're staring at your overflowing garage, your overflowing basement, and your overflowing... well, everything! It's time to get organized, and a good old-fashioned shed is the answer. But, let's be real, pre-built sheds can be a serious dent in the wallet.

That's where DIY comes in. You can build a beautiful, functional 8x12 shed and save a bunch of cash in the process. It's a weekend warrior project, sure, but trust me, the satisfaction of building your own space is priceless.

Let's Sketch Out a Plan:

First things first, we need a plan. Don't worry, you don't need to be an architect! Just think about what you want your shed to be.

Do you need a workshop? Maybe you're a woodworker, a mechanic, or a painter. You'll need space for tools, benches, and maybe even a small workbench.

Do you need storage? Think lawnmower, bikes, gardening equipment, or maybe just extra stuff that's cluttering up your garage.

Do you dream of a cozy hangout? A small shed can be the perfect escape, with a comfy chair, a table, and maybe even a small fireplace for those chilly nights.

Once you have an idea of the purpose, it's time to start sketching. Measure your space, think about the best location for your shed, and consider things like windows and doors.

Choosing the Right Materials:

The building materials are the heart of your shed. You've got options here, and your budget and desired aesthetic will guide your choices.

Pressure-treated lumber: This is a must for the foundation and bottom plates. It's resistant to rot and bugs, making it perfect for ground contact.

Framing lumber: You'll need 2x4s and maybe 2x6s for the walls and roof. Choose high-quality lumber for durability.

Sheathing: This goes on the walls and roof, adding strength and a base for siding and roofing. Plywood or OSB (oriented strand board) are common options.

Siding: Here's where you can really let your personality shine! Vinyl siding is durable and low-maintenance, but wood siding gives a classic look. You could even get creative with corrugated metal or fiber cement siding.

Roofing: Shingles are the classic choice, but metal roofing is gaining popularity for its durability and longevity.

Building the Foundation:

The foundation is the backbone of your shed. A simple concrete slab is a great option.

1. Excavate the area: Remove the top layer of soil, making sure the area is level.

2. Lay the concrete: Pour a slab about 4 inches thick, with rebar for reinforcement. Be sure to include a slope for drainage.

3. Let it cure: Concrete needs at least a week to fully cure before you can start building.

Framing Up the Walls and Roof:

Now we get to the fun part! Building the frame is like putting together a giant puzzle.

1. Start with the floor: Lay down the floor joists (2x10s or 2x12s) over the concrete foundation. Make sure they're spaced correctly and secured.

2. Build the walls: Cut the studs to the right height, attach them to the floor joists, and then add the top plate. Remember to leave openings for doors and windows.

3. Raise the walls: Get some help with this part! Carefully lift the walls into place and secure them to the floor joists.

4. Frame the roof: Build the roof trusses (or use pre-made trusses) and attach them to the top plates.

Adding the Finishing Touches:

Now it's time to turn your frame into a beautiful, functional shed!

1. Sheathing the walls and roof: Attach plywood or OSB to the frame, creating a solid base for your siding and roofing.

2. Siding and roofing: Install your chosen siding and roofing material, paying attention to details like flashing and trim.

3. Windows and doors: Install your windows and doors, making sure they're properly sealed and weatherproofed.

4. Interior finish: Add drywall, insulation, and paint to create a finished interior.

Don't Forget the Extras:

Now for the details that make your shed unique!

Lighting: Add electrical outlets and lights for both function and ambiance.

Ventilation: Install roof vents or gable vents to keep the air circulating.

Storage solutions: Shelves, pegboards, and cabinets will help you stay organized.

Personal touches: Add a doormat, a welcome sign, or some landscaping to make your shed feel like home.

You Did It!

Building your own shed is a rewarding experience. You've saved a ton of money, learned valuable skills, and created a space you can be proud of. So, go out there, grab your tools, and start building!

And hey, if you run into any questions or need help with the project, there are tons of resources available online and at your local hardware store. You've got this!

Friday, November 8, 2024

A practical guide to building a 12x20 storage shed yourself

Hey there, fellow DIYer! Ever dreamt of having a space to finally organize all that clutter? Or maybe you need a dedicated workspace for your hobbies? Building your own storage shed is a fantastic way to add value to your property, get your hands dirty, and save a bundle in the process.

A 12x20 shed is a great size â€" spacious enough for tools, lawn equipment, or even a mini workshop, but still manageable to build solo or with a friend. So, let's dive into this project, step-by-step, and make your dream shed a reality!

1. Planning is Key (But Don't Get Too Hung Up!)

Before you start buying lumber and power tools, take a moment to think about what you want your shed to be:

Location: Where will it go on your property? Consider sunlight, drainage, and access for your vehicles.

Foundation: Concrete is ideal for stability, but there are also options like gravel pads or pressure-treated skids for a more budget-friendly approach.

Doors and Windows: How many doors and windows do you need? What size? A single door is sufficient for most storage needs, but consider adding a small window for natural light if you plan on using the shed as a workspace.

Roof Style: A simple gable roof is easy to build, but you could consider a more complex design if you're feeling adventurous.

Interior Layout: Will you need shelves, benches, or a workbench? Think about how you'll use the space to maximize functionality.

Pro Tip: Sketch out your ideas. You don't need to be an architect, just a simple drawing will help you visualize the layout and calculate materials.

2. Getting Your Materials: It's a Shopping Spree (But Be Smart!)

Now for the fun part â€" the materials! Here's a basic list to get you started:

Lumber:

Pressure-treated lumber for the foundation and floor joists

2x4s for framing the walls and roof

2x6s for roof rafters (depending on your roof design)

Plywood for walls, roof sheathing, and subfloor

Fasteners:

Galvanized nails and screws

Construction adhesive

Deck screws for attaching siding and roofing

Roofing:

Shingles or metal roofing (consider your budget and climate)

Underlayment

Siding:

Vinyl, wood, or fiber cement (choose based on your budget and aesthetics)

Doors and Windows:

Pre-hung doors are easier to install

Choose windows that suit your needs and budget

Hardware:

Hinges, door handle, and lock

Window latches

Pro Tip: It's always better to overestimate your lumber needs than to run out halfway through. Consider adding 10-15% extra for cuts, mistakes, and future projects.

3. Building the Foundation: Your Shed's Strong Base

This is the most critical step. A solid foundation ensures your shed stands strong for years. Let's look at two popular options:

Concrete Slab: This requires pouring concrete, which can be a bit messy, but it offers excellent stability.

Pressure-Treated Skids: These are easier to install, especially if you don't have experience with concrete. Just make sure to level the skids properly.

Pro Tip: Consult local building codes for minimum foundation requirements.

4. Framing the Walls: A Sturdy Skeleton

Now, things start taking shape. The walls are the framework that will hold your shed together.

1. Measure and cut wall studs: Use 2x4s for the studs.

2. Attach studs to a bottom plate: This will be the base of your wall.

3. Add top plate: This piece will hold the roof supports.

4. Create wall openings: Carefully cut out openings for doors and windows.

5. Construct and brace the walls: Ensure your walls are plumb and square.

Pro Tip: Use a stud finder to locate existing utilities before drilling or nailing.

5. Building the Roof: A Shelter from the Elements

The roof is a bit more intricate, but don't worry, there are plenty of resources online to guide you.

1. Attach roof rafters: These will be the beams that support the roof sheathing.

2. Install roof sheathing: This plywood layer provides a solid surface for your roofing material.

3. Install roofing: Choose shingles, metal panels, or another material you prefer.

Pro Tip: Don't skip the underlayment. This layer provides an extra barrier against moisture and leaks.

6. Adding the Finishing Touches:

It's time to make your shed look its best!

1. Install siding: This covers the exterior walls and adds aesthetic appeal.

2. Add trim: This adds finishing touches and protects the edges of your siding.

3. Install doors and windows: Ensure they fit snugly and operate smoothly.

Pro Tip: Paint or stain your shed to protect the wood and add a personal touch.

7. Interior Finishes: Creating a Useful Space

Now for the fun part â€" making your shed functional.

1. Install subfloor: This will create a solid base for your flooring.

2. Add flooring: Choose from wood, tile, or even a simple concrete floor.

3. Install shelves, benches, or a workbench: Organize your storage space effectively.

Pro Tip: Consider adding electrical outlets and lighting for convenience and safety.

Final Thoughts: A Shed of Your Own

Building a shed is a rewarding project that gives you a sense of accomplishment and a fantastic new addition to your property. Don't be afraid to ask for help if you're stuck. There are numerous online resources, YouTube tutorials, and helpful neighbors who might offer advice.

Remember, safety first! Wear appropriate clothing and safety glasses, and always follow tool instructions. And most importantly, have fun with it! Building a shed is a fantastic opportunity to unleash your creativity and develop your DIY skills.

Thursday, November 7, 2024

Diy 10x12 shed: how to build a budget-friendly structure

Okay, so you're dreaming of a shed. Maybe you want extra storage, a little workspace, or a cozy reading nook away from the chaos of the house. But you're on a budget, right? Don't worry, my friend, because building your own 10x12 shed doesn't have to break the bank. With a little planning, elbow grease, and maybe a few helpful tips from your favorite DIY blogger (that's me, by the way!), you can have the shed of your dreams without emptying your wallet.

Let's Start With The Basics:

First things first, you gotta have a solid plan. Think about what you want to store, what kind of space you need (workbench, windows, electricity?), and how you'll use it. Don't get too fancy at this stage, we're aiming for budget-friendly here!

The Foundation:

You can get away with a gravel foundation for a shed this size, which saves you a ton of money. If your ground is level, you're golden. Otherwise, you might need to level things out with some sand or pea gravel.

The Frame:

Here's where you can really start saving. You don't need fancy, pressure-treated lumber for the frame, especially if your shed is going to be under cover. Look for good quality, standard framing lumber â€" 2x4s and 2x6s will be your best friends.

The Roof:

A simple gable roof is the easiest and most affordable option. You can even use plywood for the roof sheathing instead of OSB, which is often cheaper.

The Walls:

Here’s where you get creative! You can go with traditional siding, or save money with plywood, corrugated metal, or even recycled materials. Don’t forget to add insulation for better energy efficiency!

Let's Get Practical: Materials and Costs

Alright, let's break it down. Here’s a rough estimate of materials for a 10x12 shed, keeping it budget-friendly:

Lumber:

Framing: $200-$300 (depending on lumber prices)

Sheathing: $100-$150 (plywood or OSB)

Siding: $100-$200 (depends on your chosen material)

Foundation:

Gravel: $50-$100

Roofing:

Shingles: $150-$200

Underlayment: $50-$75

Doors and Windows:

$100-$200 (look for pre-hung doors for easier installation)

Hardware and Extras:

Screws, nails, paint: $50-$100

Total Estimated Cost: $750-$1,100 (This is a rough estimate, and prices can vary depending on your location and the materials you choose)

Remember:

Shop around: Compare prices from different lumber yards and home improvement stores.

Look for deals: Keep an eye out for sales and discounts. You might even find leftover materials from other projects.

Recycle and repurpose: Get creative with your materials! Use old doors or windows, reclaimed wood, or even corrugated metal from a local salvage yard.

Building the Structure:

Now, the fun part! Building your own shed isn't rocket science. Here's a basic breakdown of the steps:

1. Prepare the Foundation: Lay down your gravel foundation and level it out.

2. Build the Frame: Start with the floor joists, then the walls, and finally the roof rafters. Make sure everything is square and level.

3. Sheathe the Walls and Roof: Attach your chosen sheathing to the frame.

4. Install the Roof: Lay down your underlayment and then shingle your roof.

5. Add Siding: Cover your walls with your chosen siding.

6. Install Doors and Windows: Follow the manufacturer's instructions for installation.

7. Finish Touches: Add any trim, paint, and other finishing touches to complete your shed.

Essential Tools for Your Shed Building Adventure:

Measuring Tape: You can’t build a shed without one!

Level: For keeping things straight and square.

Circular Saw: For cutting lumber.

Hammer: For nailing and driving screws.

Drill: For installing screws and other hardware.

Safety Glasses: Protect your eyes!

Gloves: Protect your hands!

Ladder: For reaching those high places.

Safety First, DIYer!

Always wear safety glasses and gloves: This will protect you from splinters, debris, and other potential hazards.

Be aware of your surroundings: Make sure the area is clear of obstacles before you start working.

Take breaks: Working on a shed can be physically demanding.

Don’t lift heavy objects alone: Ask for help if you need it.

Follow the manufacturer’s instructions: Always follow the instructions that come with your building materials and tools.

Embrace the Challenge, DIYer!

Building your own shed is a rewarding experience. You’ll learn new skills, save money, and create a space you can truly be proud of. Just remember, it’s ok to ask for help if you need it, and don't be afraid to embrace the learning process. And most importantly, have fun! You’ve got this!

Budget 8x10 shed designs for practical backyard storage

Hey there, fellow backyard enthusiasts! We all know the struggle: too much stuff and not enough space. That pile of gardening tools, the winter sports gear, and maybe even a vintage record collection that's taking over your living room â€" it's time to reclaim your space with a little help from a good ol' fashioned shed. But who wants to break the bank on a fancy pre-built model? We're talking budget-friendly here, people!

Think of it like this: your 8x10 shed is going to be your personal haven, your mini-mansion in the backyard. And just like any good home, it needs a little planning and some careful consideration to ensure it's functional, stylish, and fits your needs perfectly.

Let's get down to the nitty-gritty: building an 8x10 shed on a budget.

1. The Foundation: Your Shed's Bedrock

First things first, you need a solid foundation. You've got a couple of options here, both with their own pros and cons:

Concrete Slab: This is the most durable option, offering years of stability and resistance to the elements. However, it can be the priciest, requiring professional installation. If you're a DIYer, you might want to consider a more budget-friendly option.

Wood Platform: This is where you can really save some cash! You can build a sturdy platform using treated lumber and pressure-treated posts. This is a great DIY project, but make sure you choose the right type of wood and follow building codes for your area.

2. Framing: The Skeleton of Your Shed

Once your foundation is solid, it's time to build the frame. Think of it as the bones of your shed â€" sturdy, durable, and ready to support the rest of the structure.

Lumber Choices: Don't overthink it! Standard 2x4 lumber is perfect for this size of shed. You can save money by buying the lumber in bulk, but make sure it's dry and free of cracks.

Framing Techniques: You've got two main options here:

Traditional Framing: This involves using studs, plates, and joists to create a solid framework.

Wall Panel Framing: This uses pre-fabricated wall panels, which are quicker and easier to assemble. This might cost a little more, but it can be a great option for beginner DIYers.

3. Roof Design: Keeping the Elements at Bay

Your roof is your shed's shield from rain, snow, and sun.

Simple Gable Roof: This is a classic and budget-friendly option. It's straightforward to build and offers good water drainage.

Lean-to Roof: This is the simplest option, featuring a single slope. It's perfect for a small shed, but may not offer as much headroom as a gable roof.

4. Siding: The Shed's Outer Shell

Your siding choice is not only functional, but also adds personality to your shed.

Budget-Friendly Options: Consider using vinyl siding, corrugated metal, or even treated plywood for a more rustic look.

Adding Insulation: If you plan on using your shed for more than just storage, you might want to consider adding insulation to your walls and roof. This will make your shed more comfortable and help keep it warmer in the winter and cooler in the summer.

5. Doors and Windows: Access and Light

Don't underestimate the importance of doors and windows!

Entry Doors: A single, solid door is sufficient for an 8x10 shed. You can even go for a double door if you need to store larger items.

Windows: A couple of small windows will provide natural light and ventilation. You can use pre-built windows or even cut your own out of plywood and add clear plastic sheeting.

6. Finishing Touches: The Finishing Touches

Once the structure is complete, it's time for the finishing touches:

Flooring: Choose a durable flooring option that's easy to clean. Concrete, plywood, or even outdoor carpet are great choices.

Painting and Finishing: Give your shed a fresh coat of paint or stain to protect it from the elements and enhance its look.

Design Ideas: Make Your Shed Stand Out

Now, let's talk about the fun stuff â€" designing your shed to make it uniquely yours!

Vertical Storage: Maximize vertical space with shelves, pegboards, and hanging storage solutions.

Workbenches: Add a sturdy workbench for projects and hobbies.

Lighting: Install a light fixture or two for a well-lit space.

Garden Storage: Dedicate a section to gardening tools, pots, and seeds.

Outdoor Kitchen: Imagine a tiny outdoor kitchen complete with a mini-fridge and a countertop for preparing snacks and drinks.

Guest Room: If you have guests over often, consider adding a comfortable cot and some storage for a mini-guest room.

DIY vs. Hiring a Contractor: Weighing Your Options

DIY: You'll save a lot of money building your own shed, and you'll have the satisfaction of completing it yourself. Just make sure you have the time, tools, and skills to handle the project.

Hiring a Contractor: This is a good option if you lack time, experience, or the tools. A contractor can ensure the shed is built to code and will handle all the heavy lifting.

Safety First!

Building Codes: Always check local building codes and regulations.

Safety Equipment: Wear appropriate safety gear when working on your shed.

Power Tools: If you're using power tools, make sure you know how to use them safely.

Conclusion: A Budget-Friendly Backyard Haven

With a little planning and some elbow grease, you can build a practical and stylish 8x10 shed on a budget. Remember, this is your space â€" so design it to reflect your needs and personality. So, grab your tools, unleash your creativity, and get ready to build a backyard haven that will help you regain control of your stuff and your space!

How to build a 12x16 garden shed in a weekend

Alright, you're ready to tackle a weekend project that'll give you bragging rights for months? Let's build a 12x16 garden shed! It's a bit of a challenge, but with the right plan and a sprinkle of elbow grease, you'll be storing your tools and lawnmower in style by Sunday evening.

Step 1: The Foundation - Setting the Stage

Think of the foundation as the bedrock of your shed, the solid base that'll keep your structure standing tall for years to come. Here's the deal:

Concrete Slab: This is the gold standard, providing rock-solid stability and lasting strength. You'll need to dig a level area, pour concrete, and let it cure properly. It might take a bit longer than a weekend, but it's worth the extra effort.

Pressure-Treated Skirts: This option is faster and more budget-friendly. You'll simply be laying down pressure-treated lumber around the perimeter, acting as a raised foundation. This works well on relatively level ground.

Gravel Pad: A gravel pad is another good option if your ground is relatively level. It's less labor-intensive than concrete but might not be as stable.

Step 2: Framing - The Backbone of the Shed

Framing is the heart of the shed, the structural skeleton that gives it shape. Here's what you need to know:

Materials: You'll need pressure-treated lumber for the base, and standard lumber for the walls, roof, and door. Don't forget the essential hardware like nails, screws, and joist hangers.

Layout: Start by laying out your foundation based on your chosen method. Then, using a level, mark the positions for your wall studs and roof joists. Cut the lumber to size, ensuring everything is square and level.

Wall Construction: Assemble your walls by attaching studs to the base plate and connecting them with top plates. You'll likely want to use a framing square to ensure everything is perfectly square.

Roof Framing: Once the walls are complete, you can start framing the roof. This involves creating trusses (if you're going with a trussed roof) or cutting rafters and attaching them to the top plates. Remember to account for overhangs.

Step 3: Siding - The Outer Layer

Now comes the fun part - giving your shed a face! Here's what you need to know:

Siding Choices: There are many siding options like vinyl, wood, metal, and even composite materials. Consider your budget, aesthetics, and maintenance requirements.

Installation: Follow the manufacturer's instructions for installation. Usually, it involves attaching the siding panels horizontally or vertically to the wall framing. Use a level and plumb line to ensure everything is straight.

Flashing and Trim: Don't forget about flashing around windows, doors, and other openings. This helps prevent water intrusion. You'll also need to add trim for a professional finish.

Step 4: Roofing - Weatherproof Protection

The roof is your shed's first line of defense against the elements. Here's what you need to know:

Roofing Choices: There's a world of roofing options, from traditional asphalt shingles to metal roofing. Choose one that fits your budget and style.

Installation: Laying down the shingles or metal panels is often straightforward. Make sure you follow the manufacturer's instructions carefully, paying attention to overlaps and nailing patterns.

Ventilation: Install adequate ventilation to prevent moisture buildup in the attic. Roof vents or soffit vents are great options.

Step 5: Doors and Windows - Access and Light

Doors and windows add functionality and style to your shed. Here's what you need to know:

Door Choices: You have a variety of door options, from simple single doors to double doors with windows. Choose a door that suits your needs and fits the overall design.

Window Choices: Consider the size and number of windows you need to provide adequate natural light. Don't forget to install flashing around the window openings.

Installation: Install the door and windows following the manufacturer's instructions. Ensure everything is securely fastened, level, and plumb.

Step 6: Finishing Touches - Adding the Wow Factor

Now it's time to put the finishing touches on your shed, turning it from "just a shed" to a "stylish haven."

Painting: Give your shed a fresh coat of paint in your favorite color to complement your garden or outdoor space.

Flooring: Install flooring inside the shed, whether it's simple plywood, vinyl tiles, or even concrete. This will create a clean and comfortable interior.

Shelving and Storage: Maximize the space by adding shelves, cabinets, and other storage solutions. You can create a custom layout to fit your needs.

Landscaping: Finish off the exterior with landscaping. Plant flowers, shrubs, or ground cover around the shed to create a welcoming and visually appealing space.

Remember, Safety First!

Power Tools: Be careful when using power tools like saws and drills. Wear safety glasses and ear protection.

Ladder Safety: Always use a sturdy ladder and make sure it's placed on a stable surface.

Weather Conditions: Avoid working in extreme weather conditions like rain or strong winds.

The Power of Teamwork

Building a shed can be a fun family or friend project. Enlist help from others, and remember to work together, communicate clearly, and have fun!

Tips for Success:

Plan Ahead: Plan your project carefully, gathering materials and tools before you start.

Measure Twice, Cut Once: Accuracy is key! Take your time and double-check measurements before cutting lumber.

Seek Help: Don't hesitate to ask for help from experienced builders or friends.

Enjoy the Process: Building a shed is a rewarding experience. Take your time, learn from your mistakes, and have fun along the way.

Now you're ready to tackle the project! With a little effort and the right tools, you can create a functional and stylish garden shed that will serve you for years to come. Happy building!

Diy garden shed plans: affordable and easy designs

Hey there, green thumbs! So you're dreaming of a tidy, organized garden, but your tools are scattered like wildflowers and your seeds are hiding in a dusty old box? Don't despair! Building a garden shed is easier than you think, and it doesn't have to break the bank. Let's dive into some DIY shed plans that are affordable, easy, and totally doable.

Step 1: The Great Design Debate

First things first, let's figure out what kind of shed you need. Do you want a small, cozy space for just your basic tools, or are you dreaming of a potting bench and a place to store your growing collection of gardening gadgets?

Small & Sweet: If you're going for minimal, a 6x8 or 8x8 shed is perfect. They're easy to build and won't take up too much space.

Mid-Sized Marvel: For a bit more room, consider a 10x12 or 12x16 shed. You'll have space for tools, potting supplies, and maybe even a small workbench.